Continuous Steamer

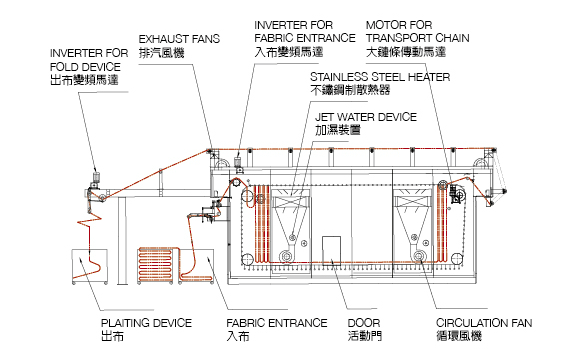

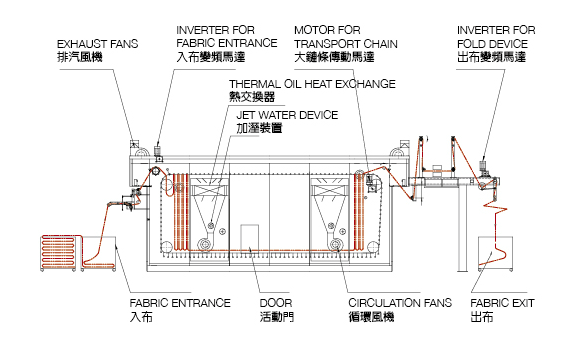

Description

Continuous Steamer is used as an ager for color fixation after printing of textiles. The unique formation and control of saturated steam quality.It is achieve the fixing quality of colours.

Mechanical Features

- This steamer is applicable to a board range of fabric made of various materials, from the fine synthetic fabric to the thick pile fabric.

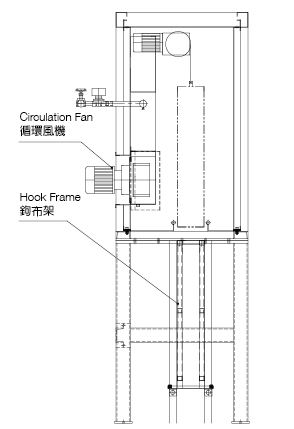

- A special un-tension designed is hanging loop for fabric from outside to inside. There are two pairs of roller, guide fabric and “spray pipe” are coordinated together, then hanging loop will go straightaway.

- “Spray pipe” functions: to prevent fabric moving, increase humidity for calico looks more colorful. Also to avoid the fabric becomes goffer and roll together.

- Hanging rods are unique designed of aluminum alloy profile, no need of anti-slip inserts and therefore allowing longer effective duration.

- The advanced design of “closed steam chamber”, thermal oil heat exchange. and “stainless circulation fan.” Helps rapidly raise the temperature to a desired level in the steam chamber. Effectively optimize the thermal energy, distributed the steam evenly in the chamber and keep the temperature in constant uniformity.

- The specific steam regulation system which maintains the moisture at the best operation level in constant degree irrespective of how much steam is supplied.

- There are several injection system for saturated steam to raise the temperature in the steam chamber.

- The top of the steam chamber is designed with the spiral heating coil to prevent the steam from forming a condensed drip.

- A specially designed of water atomizer to keep the temperature extremely stable in the steam chamber.

- Superheated system use heat exchange to quickly increase the temperature had set up. There is oil control valae which can control temperature very accurate at ±1℃.

- Steam chamber has several windows which is easy for the operator to see the condition.

- Steam machine is use glass fiber to partition the heat which is accord with environmental require.

| MODEL |

ST-125 |

ST-250 |

ST-350 |

ST-400 |

ST-450 |

| Liner capacity of fabricmt |

100 |

250 |

350 |

400 |

450 |

| Working speedmt/min |

3-20 |

4.5-30 |

7-45 |

7.6-50 |

7.6-50 |

| Dwell timemin |

5-33 |

8-55 |

8-50 |

8-53 |

9-60 |

| Standard roller width(A)mt |

2.0-3.9 |

| Temperature when working in saturation℃ |

100-105 |

| Temperature when working in H.T. condition℃ |

170-180 |

| Temperature when working with hot air℃ |

90-180 |

| Average steam consumptionkg/h |

300-400 |

600-900 |

700-1,100 |

1,000-1,500 |

1,000-1,500 |

| Install thermal powercal/h |

100,000 |

200,000 |

300,000 |

400,000 |

400,000 |

| Install electric powerkw |

13 |

20 |

25 |

30 |

30 |

| Lengthmt |

8.9 |

14.4 |

17.2 |

18.6 |

20 |

| Widthmt |

Roller width A+2.35 |

Laboratory Steamer

Description

The laboratory steamer has basic extension design from loop steamer. It is extremely useful for the development work of dyestuff and chemical manufactures. It reproduces the exact steaming conditions of our loop steamer machine whether in saturated steam from temperature of 100℃-105℃ or in superheated steam from temperature of 175℃-180℃. The inside of machine is made of 304 stainless steel. It has been designed to work as closed-type machine and steam recycling inside the chamber. There is an electric-lift door at the bottom. It is equipped with automatic temperature control and moisture control.

| MODEL |

ST-01 |

ST-02 |

ST-03 |

| Capacity of sample to be steammt |

3 |

10 |

20 |

| Working temperature in saturated steam℃ |

100-105 |

100-105 |

100-105 |

| Working temperature in superheated steam℃ |

175-180 |

175-180 |

175-180 |

| Steam consumption in saturated steamKg/h |

50 |

80 |

100 |

| Install electric power in saturated steamkw |

0.4 |

0.4 |

0.4 |

| Install electric power in superheated steamkw |

10 |

13 |

16 |

| Steam pressure supplyKg/cm2 |

4-5 |

4-5 |

4-5 |

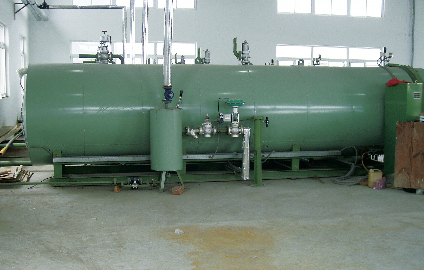

High Pressure High Temperature Automatic Steamer

Description

There are three options of control:“temperature”, “humidity”and “pressure” of control which can be used.

Thus ensuring the colour fixing process. It is simple operation and safety.

Mechanical Features

- Applicable to the steaming of various printed cloth, such as Cotton, Acrylic, Nylon, Polyester, and fibres.

- Select appropriate temperature or pressure for operation, thus ensuring the colour fixing.

- Hydraulic rotation inserting operation is adopted for the door thus making the operation to be simple with high safety factor.

- As the device is specially designed for temperature controlled and steam pressure has been controlled in proportion, customers can select either one of our products to serve the operation purpose.

- Humidity control valve is provided thus the humidity can be adjusted at will.

- Cloth hanging rack can be designed at the request of the customer depending on the kinds of cloth to be steamed.

| MODEL |

SBV-11 |

SBV-12 |

SBV-13 |

SBV-14 |

| Specificationmm |

2000φ×2440L |

2200φ×2440L |

2200φ×3050-4880L |

2400φ×3050-4880L |

| Applicable width of printing clothINCH |

50” |

60” |

60” |

68” |

| Maximum capacityM |

680 |

680 |

850-1350 |

850-1350 |

| Time for anodizingMIN |

10-60 |

10-60 |

10-60 |

10-60 |

| Working temperature℃ |

100-130 |

100-130 |

100-130 |

100-130 |

| Maximum application pressureKg/cm2 |

3 |

3 |

3 |

3 |

| Diameter of steam pipemm |

40 |

50 |

50 |

50 |

| Relief valvemm |

50 |

65 |

65 |

65 |

| Drainage valvemm |

32 |

40SBV-12 |

40SBV-13 |

40SBV-14 |

| MODEL |

SBV-15 |

SBV-16 |

SBV-17 |

| Specificationmm |

2600φ×3050-4880L |

2800φ×3050-4880L |

3000φ×3050-4880L |

| Applicable width of printing clothINCH |

75” |

80” |

88” |

| Maximum capacityM |

980-1550 |

980-1550 |

980-1550 |

| Time for anodizingMIN |

10-60 |

10-60 |

10-60 |

| Working temperature℃ |

100-130 |

100-130 |

100-130 |

| Maximum application pressureKg/cm2 |

3 |

3 |

3 |

| Diameter of steam pipemm |

50 |

50 |

50 |

| Relief valvemm |

65 |

65 |

65 |

| Drainage valvemm |

50SBV-15 |

50SBV-16 |

50SBV-17 |

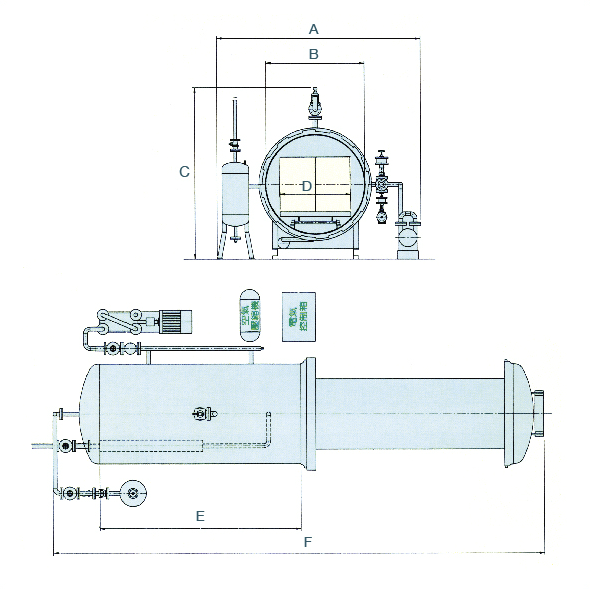

SBV Automatic Vacuum Steam Setter

Description

Applicable for the type-fixing of tight twist yarn, soft twist yarn, false-twist yarn and synthetic twist yarn. Simple maintaence and easy operation. Thus ensure that the quality is stability.

Mechanical Features

- Applicable to type fixing of tight twist yarn, soft twist yarn, false-twist yarn and synthetic twist yarn.

- Select appropriate temperature and vacuum for operation thus ensuring the stability of quality and type fixing.

- Temperature and vacuum in the steamer are so even that the inner and outer layer of the yarn quality can be maintained.

- Excellent, design, simple maintenance and easy operation.

| TYPE/MM |

A |

B |

C |

D |

E |

F |

| SBV-6 |

2500 |

1200 |

2100 |

860 |

2000 |

5100 |

| SBV-7 |

2500 |

1200 |

2100 |

860 |

2440 |

6000 |

| SBV-8 |

2500 |

1200 |

2100 |

860 |

3050 |

7200 |

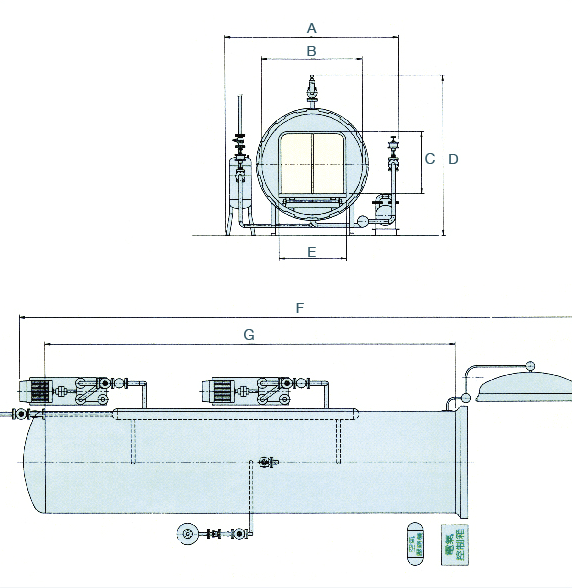

| TYPE/MM |

A |

B |

C |

D |

E |

F |

G |

| SBV-9 |

2600 |

2400 |

930 |

1500 |

1000 |

5550 |

3050 |

| SBV-10 |

2600 |

2400 |

930 |

1500 |

1000 |

8550 |

6100 |

| MODEL |

SBV-6 |

SBV-7 |

SBV-8 |

SBV-9 |

SBV-10 |

| Max. allowable pressureKg/cm2 |

3 |

3 |

3 |

3 |

3 |

| Max. allowable temperature℃ |

143 |

143 |

143 |

143 |

143 |

| Body size(dia. x shell length)mm |

ψ1200×2000L |

ψ1200×2440L |

ψ1200×3050L |

ψ1500×3050L |

ψ1500×6100L |

| Inside volumem3 |

2.78 |

3.28 |

3.97 |

6.27 |

11.66 |

| Working temperature range℃ |

50-140 |

50-140 |

50-140 |

50-140 |

50-140 |

| Operating time rangemin |

10-60 |

10-60 |

10-60 |

10-180 |

10-180 |

| Vacuum pumpkw |

V-W5.5 |

V-W7.5 |

V-W7.5 |

V-W11 |

V-W11×2 |

| Steam valvemm |

25 |

25 |

40 |

40 |

50 |

| Watermm |

20 |

20 |

20 |

25 |

25×2 |

| Drainmm |

40 |

40 |

40 |

50 |

65 |

| Vacuum break valvemm |

25 |

25 |

40 |

40 |

40×2 |

| Electricitykw |

7.5 |

9 |

9 |

14 |

25 |